rfgumby

Administrator

Member

Offline Offline

Location: Minneapolis, Minnesota, USA

Posts: 18,372

|

|

« Reply #45 on: January 12, 2013, 11:28:09 PM » |

|

Hurry up! Hurry up! We need a report!  |

|

|

|

|

Logged

Logged

|

Scott

Like a leper messiah When the kids had killed the man I had to break up the band -David Bowie

|

|

|

Bonzo

Member

Offline Offline

Age: 46

Location: Milan, Italy

Posts: 1,145

My name is Marco, best known as Bonzo!

|

|

« Reply #46 on: January 13, 2013, 11:14:22 AM » |

|

Hurry up! Hurry up! We need a report!  Are you quoting me?!?!  Johan, I really admire your craftsmanship! Nice work and nice report too! |

|

|

|

|

Logged

Logged

|

|

|

|

Johan

Member

Offline Offline

Age: 63

Location: Helsingborg, Sweden

Posts: 1,119

|

|

« Reply #47 on: January 13, 2013, 09:39:14 PM » |

|

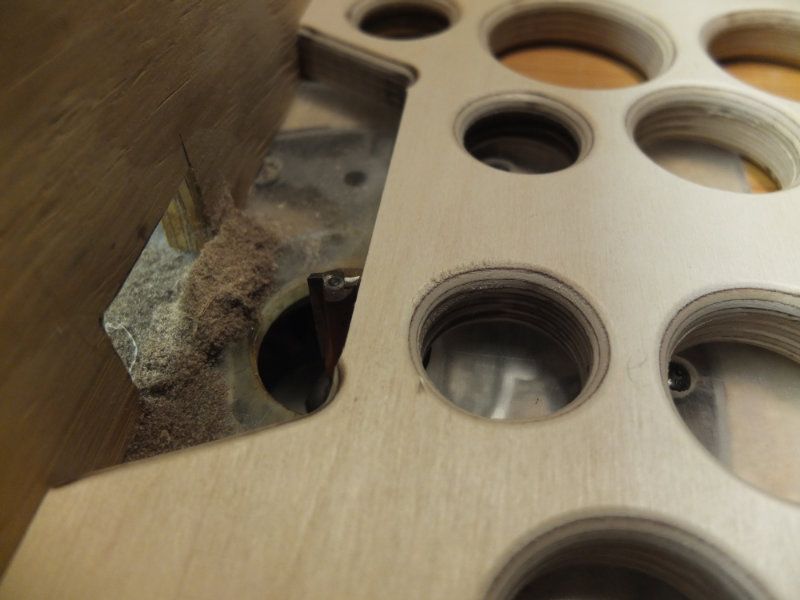

I know, I know. Actually I want to listen to it immediately. Last speaker I made was more than 30 years ago, and that didn't turn out very well. This time I have decided to make it as good as I can. That means I am advancing rather slow. Let's continue! I put the template on the brace piece and mark the holes:  After some trials I found that it is easiest to cut the holes with a hole saw and then trim the holes with the router, using the template as a guide:   Now I have got two braces that look like this:  And it is time for another test fit:  The driver cut out needs some mm more cut away. The brace doesn't reach the front panel. I intentionally made the template like that. |

|

|

|

|

Logged

Logged

|

Johan

WL70 - ΨAΘIN MS-12B - Icon Audio ST40 - Fostex FF125wk Fonkens

|

|

|

rfgumby

Administrator

Member

Offline Offline

Location: Minneapolis, Minnesota, USA

Posts: 18,372

|

|

« Reply #48 on: January 14, 2013, 12:18:01 AM » |

|

If you can use a round over bit or a 45 degree bevel router bit on those holes, it should smooth out the air passing through all those holes in the brace. It may make it stronger bevel inch those hole edges too.  Like radius' on port holes to reduce "chuffing". |

|

|

|

|

Logged

Logged

|

Scott

Like a leper messiah When the kids had killed the man I had to break up the band -David Bowie

|

|

|

Johan

Member

Offline Offline

Age: 63

Location: Helsingborg, Sweden

Posts: 1,119

|

|

« Reply #49 on: January 19, 2013, 08:31:03 PM » |

|

Thanks Scott for a good idea! I even checked the validity of rounding the holes over. There is a VERY small potential theoretical benefit, but it is mostly aesthetic, and since inside the box, of benefit to the builder. Of course that means I just had to round the holes  :  I doubt though that the hole rounding over will make the brace any stronger. The stress concentration I think you refer to is taking place at inside corners not outside corners, at least as I can remember it. |

|

|

|

|

Logged

Logged

|

Johan

WL70 - ΨAΘIN MS-12B - Icon Audio ST40 - Fostex FF125wk Fonkens

|

|

|

Johan

Member

Offline Offline

Age: 63

Location: Helsingborg, Sweden

Posts: 1,119

|

|

« Reply #50 on: January 20, 2013, 09:15:10 PM » |

|

Today I trim the brace for a proper fit at the driver back. The router table is doing well:  The driver datasheet says the distance to the back is 57.5 mm. I measure it to be 58 mm. I make several cuts it small steps and it seems my measurement is correct. Here's a test fit:  Here are the two with the drivers and braces temporary in position:  The last step is trimming the brace top and back a little for a good fit to the speaker top and the backside. Then I put glue on and clamp the brace and the top to the rest:  |

|

|

|

|

Logged

Logged

|

Johan

WL70 - ΨAΘIN MS-12B - Icon Audio ST40 - Fostex FF125wk Fonkens

|

|

|

Johan

Member

Offline Offline

Age: 63

Location: Helsingborg, Sweden

Posts: 1,119

|

|

« Reply #51 on: January 26, 2013, 10:42:49 PM » |

|

Both boxes are glued and I am planning the cutting of the front chamfers.

Some problems have showed up.

The table saw has a fixed saw blade. Instead the table can be tilted up to 45 degrees from horizontal. To fix the speaker box to the guide I think I need an additional support. I have to make one myself as there are no suitable parts on the saw that can be used.

Also, when the table is tilted to 45 degrees, the saw blade touches the table insert a lot, although the insert is chamfered. Perhaps there has been more inserts for the saw, but it is 60 years old so those parts are now missing. I have even tried a thinner saw blade, but simply isn't enough. So, I have to make an insert with a wider slot for the saw blade.

|

|

|

|

|

Logged

Logged

|

Johan

WL70 - ΨAΘIN MS-12B - Icon Audio ST40 - Fostex FF125wk Fonkens

|

|

|

Johan

Member

Offline Offline

Age: 63

Location: Helsingborg, Sweden

Posts: 1,119

|

|

« Reply #52 on: February 10, 2013, 08:56:11 PM » |

|

|

|

|

|

|

Logged

Logged

|

Johan

WL70 - ΨAΘIN MS-12B - Icon Audio ST40 - Fostex FF125wk Fonkens

|

|

|

Johan

Member

Offline Offline

Age: 63

Location: Helsingborg, Sweden

Posts: 1,119

|

|

« Reply #53 on: February 10, 2013, 11:01:33 PM » |

|

Here are the both interesting parts, the speaker boxes with the newly cut front chamfers:   Coming directly from the saw. I was a bit worried on how exact I could cut. It is a deep cut, and it is large angle. I don't want the edges to tear out when cutting. Don't cut to much and don't cut to little. But all it all worked very well. The cut required two persons, one at each end of the table saw, otherwise it would have been difficult to move the speaker with good enough control all the way. |

|

|

|

« Last Edit: February 10, 2013, 11:03:51 PM by Johan »

|

Logged

Logged

|

Johan

WL70 - ΨAΘIN MS-12B - Icon Audio ST40 - Fostex FF125wk Fonkens

|

|

|

rfgumby

Administrator

Member

Offline Offline

Location: Minneapolis, Minnesota, USA

Posts: 18,372

|

|

« Reply #54 on: February 11, 2013, 02:19:10 AM » |

|

Those are awesome. I had to laugh about the "theoretical benefit" of the hole chamfers, but I see you're like me and I would have done it too as long as I was in there. You can't do it later.  Great work so far, and that old saw is really a gem. |

|

|

|

|

Logged

Logged

|

Scott

Like a leper messiah When the kids had killed the man I had to break up the band -David Bowie

|

|

|

reinderspeter

Administrator

Member

Offline Offline

Age: 61

Location: Amsterdam

Posts: 6,666

|

|

« Reply #55 on: February 11, 2013, 09:32:23 AM » |

|

Those are awesome.

They are that  |

|

|

|

|

Logged

Logged

|

Peter PTP Audio for Lenco based idler drive Turntables, Chipamps and Power Controllers. |

|

|

Rotsch

Member

Offline Offline

Age: 60

Location: Germany "@the lost west"

Posts: 3,531

Follow the white rabbit.....

|

|

« Reply #56 on: February 11, 2013, 09:55:23 AM » |

|

Those are awesome.

They are that  This will be rough n rigid stuff  |

|

|

|

|

Logged

Logged

|

Roger  "To play a wrong note is insignificant. To play without passion is inexcusable." "To play a wrong note is insignificant. To play without passion is inexcusable." -Ludwig Van Beethoven

|

|

|

Johan

Member

Offline Offline

Age: 63

Location: Helsingborg, Sweden

Posts: 1,119

|

|

« Reply #57 on: February 14, 2013, 10:27:02 PM » |

|

The back panels have been adjusted and screwed on. After some sanding I just couldn't resist a test fit:   Yes, the cable is connected and there is sound! The sound seems very promising, a little shouty perhaps but very detailed. At the moment there is no stuffing in the boxes and the amp is a very cheap and simple one, so it can only become better. |

|

|

|

|

Logged

Logged

|

Johan

WL70 - ΨAΘIN MS-12B - Icon Audio ST40 - Fostex FF125wk Fonkens

|

|

|

Johan

Member

Offline Offline

Age: 63

Location: Helsingborg, Sweden

Posts: 1,119

|

|

« Reply #58 on: February 17, 2013, 12:56:21 AM » |

|

|

|

|

|

« Last Edit: February 17, 2013, 10:53:17 AM by Johan »

|

Logged

Logged

|

Johan

WL70 - ΨAΘIN MS-12B - Icon Audio ST40 - Fostex FF125wk Fonkens

|

|

|

fetteler

Member

Offline Offline

Age: 68

Location: Staffordshire Moorlands UK

Posts: 4,539

|

|

« Reply #59 on: February 17, 2013, 01:36:41 AM » |

|

Johan,

They are quite simply magnificent and look superb. You are a talented man and your workmanship is absolutely first class. Well done indeed.

How do you intend to finish the cabinets?

Cheers,

Steve.

|

|

|

|

|

Logged

Logged

|

Have nothing in your house that you do not know to be useful, or believe to be beautiful.

I try to spell correctly - sometimes the dyslexia wnis!

|

|

|

|